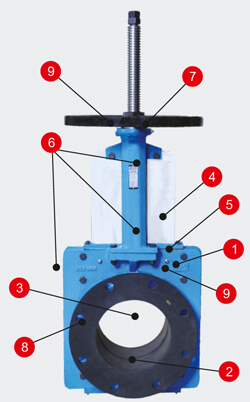

Knife Gate Valve

Application

Powder handling in silos

Pulp and Paper Plants

Slurry Handling (Chemical Plant & Process Industries)

Water and Sewage Applications

Pneumatic Conveying Systems

High temperature services

Mining & Power Plants

MATERIAL OF CONSTRUCTION

Body : Made up of one piece solid, rugged and heavy duty casting with flanges. Standard is Ductile Iron. SS 304, SS 316, SS 316L, Alloy 20, CD4MCu available on request.

Knife Gate : High tensile metal sheet SS 316L as standard. Alloy 20, Hestalloy etc available upon request.

Seat / Sleeve : Available in all materials as per requirement of application. Natural Rubber, Neoprene, EPDM, Viton, Hypalon etc.

Packing : Smooth well machined packing chambeer to provide iniform compression of packing and gives zero leakage. PTFE/high temperature graphite asbestos, food grade packing etc available as per application requirement.

Hand Wheel : Cast Iron, epoxy painted.

Application

Pinch valve finds its best application in handling corrosive slurry, abrasive media, liquid with solid suspensions and many others, which are difficult to handle with seat valve. Pinch valves are also best suited for Vacuum service

Range

The flange of the pinch valve can be supplied in accordance to BS, DIN, ASA & IS dimensions. The range for the valve is from 15 mm TO 300 mm. Higher size range can also be developed on request.

When open, the KGV Valve’s reinforced elastomer sleeves seal against each other and provide a 100% full-port opening which minimizes turbulence and wear. In this open position, the seats isolate and protect all metal parts of the valve from coming in contact with the process. When closed, the sleeves provide a drop-tight seal in both directions.

Available Sizes 3"-36"

Abrasivion-Resistant Slurry Sleeves are Field Replaceable, Provide Bi-directional, Drop-Tight Shut-off and Eliminate the Need for Packing

100% Full-Port Design

Heavy-duty 316L stainless Steel Get

Wiper Blade Cleans debris from Gate as it strokes

Open/Close Lock-Out feature (optional)

Robust Corrosion-Resistanct ductile iron yoke

Slotted Flange Holes for Easy through-Bolt installation

Grease Fittings for Gate and Stem Lubrication

SUPERIOR SLEEVE DESIGN

JEC valve seat is made up of two highly resistant, long lasting sleeves made up of natural rubber with metallic core. It's well studied and patented hollow design allows for maximum flexibility on passing through the gate, minimizing the effort necessary for its operation.

The two sleeves are in permanent contact with each other so that there is total flow. Considering that the knife gate valve is specially designed to work with abrasive slurries, this design of sealing provides constant protection the body because the working media is not in direct contact with the body.

For easy maintenance the sleeves can be fully replaced from the outside of the valve as a complete unit and no need of flange rubber gaskets to make tightness between the valve and flanges.