Gate Valve

Application

Oil, Gas, Air Slurries, Heavy liquids, Steam, Noncon densing gases, Corrosive liquids

Best Suited For

Frequent on-off service Processes where “instantly” large flow is needed

Advantages

High Capacity, Tight Shutoff, Low Cost, Little resistance to flow

Limitations

Cannot be used for pressure control

Cavitate at low pressure drops

Cannot be used for throttling

RECOMMENDED USES

Fully open/xlosed, non-throttling

Infrequent operation

Minimal fluid trapping in line

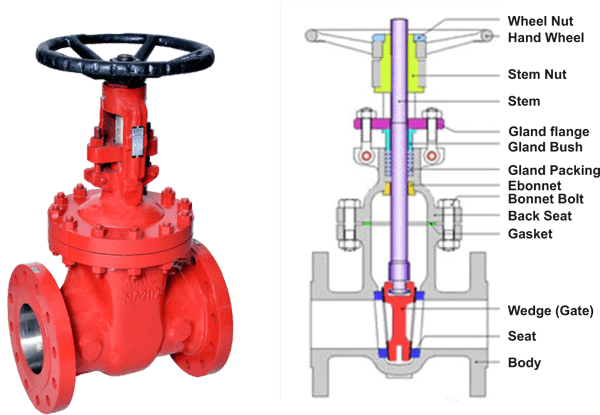

JEC Gate Valves are Outside Screw, Rising Stem, Bolted Bonnet Construction, Threads are away from the line fluid and easy to lubricate.

Gate Valve

OS & Y Type, Rising Stem, Bolted Bonnet

Design Standard: API 600

Size Range - 1" to 12"

Pressure Rating - 125# / 150# / 300#

End Connection Flanged End

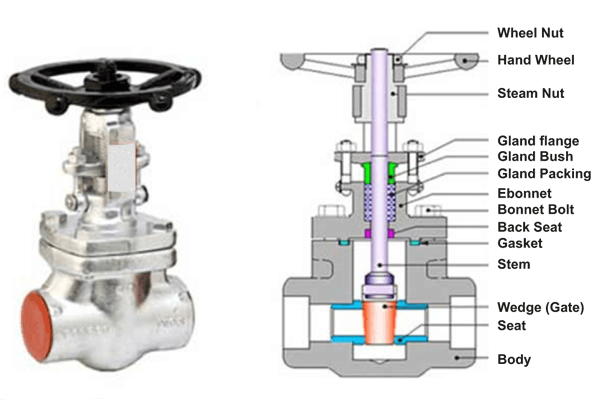

Forged Steel Gate Valve

OS & Y Type, Rising Stem, Bolted Bonnet

Design Standard: API 602

Pressure Rating: 800# / 1500#

End Connection : Screwed / Socket Weld / Butt Weld End

Material Of Construction

| Cast Iron | IS 210 Gr FG 200 |

|---|---|

| Cast Carbon Steel | ASTM A 216 Gr WCB |

| Cast Stainless Steel | ASTM A 351 Gr CF 8/CF 8M |

| Forged Carbon Steel | ASTM A 105 |

| Forged Stainless Steel | ASTM A 182 Gr F304 / F316 |

| End Connection | Screwed AS PER BSP/BSPT/NPT |

| Socketweld | AS PER ANSI B 16.11 |

| Flanged | AS PER ANSI B 16.5 |

| Pressure Rating | ASA 125#, 150#, 300#, 600#, 800# |

| Engineering Option | Gear Operated, Electrical Actuated, |

| Size Range | 15 mm to 300 mm |